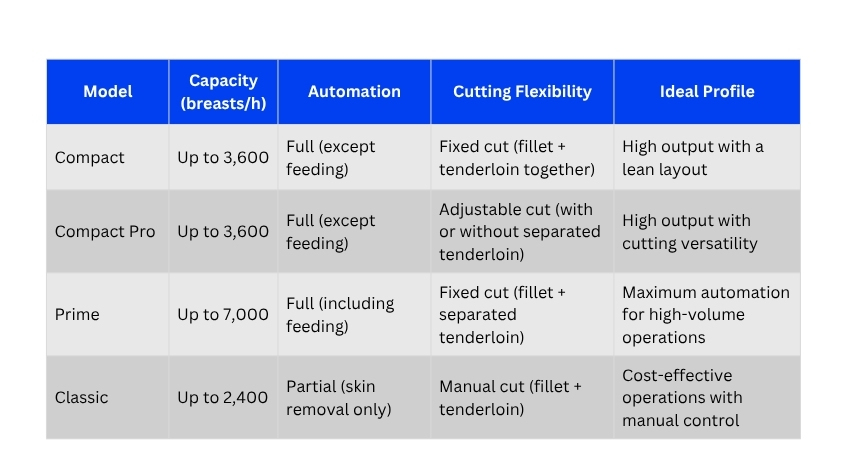

Compact, Compact Pro, Prime, or Classic?

Meitech’s line of Breast Deboners was developed to meet the needs of various types of poultry processors. From plants taking their first steps toward automation to large-scale operations seeking maximum yield, there’s a model suited for every scenario.

Below, we highlight the main differences between each version and the type of plant each model is best suited for.

1. Breast Deboner | Compact

If your plant needs to boost productivity without significantly increasing occupied space, the Compact is the ideal choice. It performs the deboning process fully automatically, with manual loading and efficient extraction of fillets with tenderloins. The result? Standardized cuts with minimal need for manual trimming.

Recommended for: Plants with consistent daily volume that need automation without major investment or space expansion.

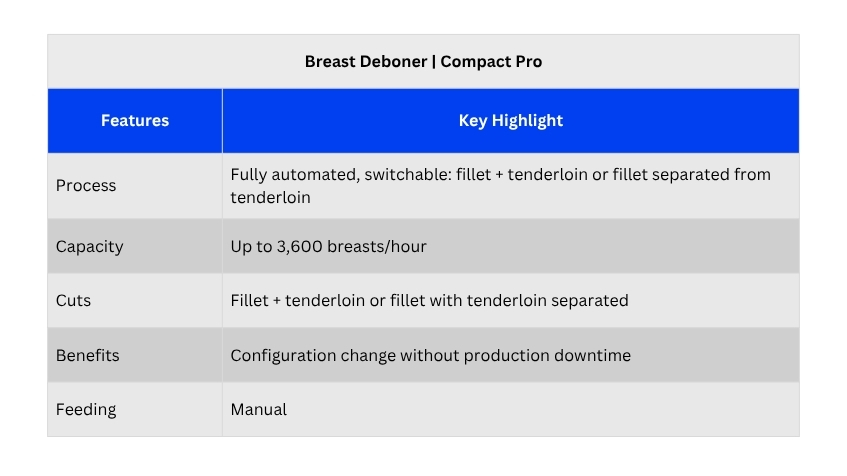

2. Breast Deboner | Compact Pro

The Compact Pro is a direct evolution of the Compact model. It maintains the same level of automation and yield, but adds operational versatility. With this model, it’s possible to switch between two cutting configurations:

Fillet with tenderloin attached

Fillet and tenderloin separated

This switch can be done quickly and easily, with no long downtime, making the line more adaptable to market demands.

Recommended for: Medium to large operations needing agility to switch between different commercial requirements.

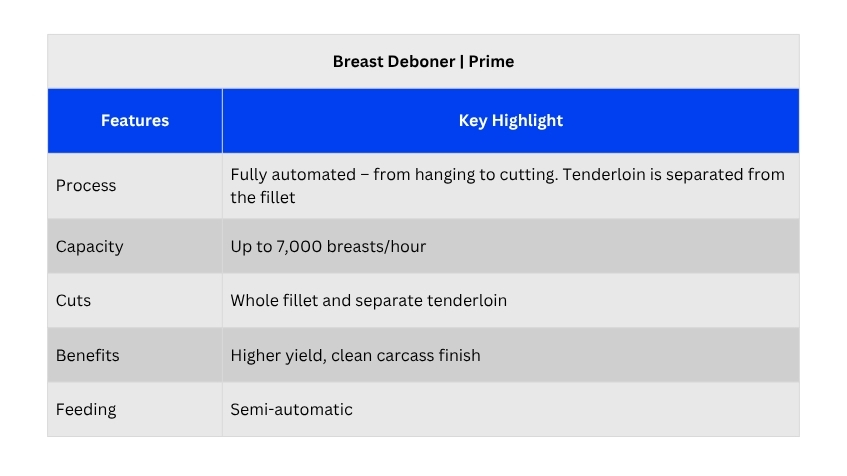

3. Breast Deboner | Prime

The most automated model in the line, featuring semi-automatic loading and a fully continuous deboning process — from hanging to tenderloin removal. The Prime delivers high productivity with minimal human intervention, ideal for operations that prioritize standardization and labor reduction.

Recommended for: Large poultry processing plants looking for maximum productivity and traceability, with fully automated hanging and deboning.

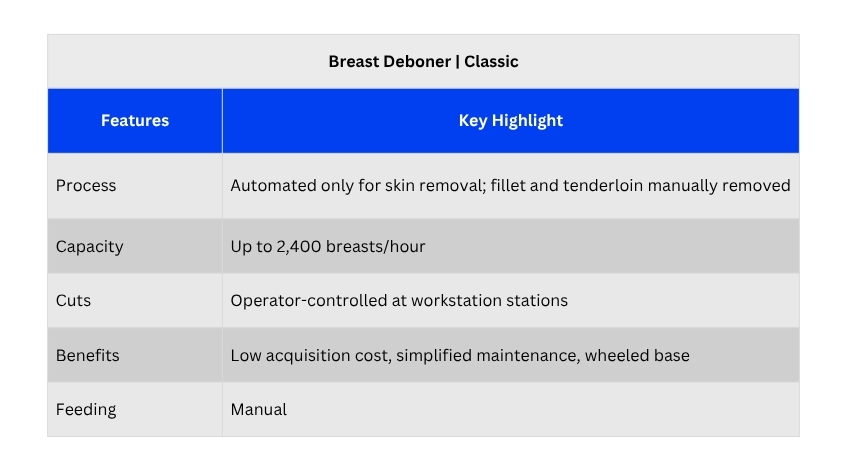

4. Breast Deboner | Classic

The Classic is the most affordable option in Meitech’s lineup. Its differential lies in the balance between automation and manual operation: skin removal is performed automatically, while the fillet and tenderloin cuts are done manually by operators.

Recommended for: Small and medium-sized companies that require reliable yield with the lowest initial investment.

Which model is right for your plant?

Conclusion

The ideal Breast Deboner for your plant depends on factors such as the scale of your operation, the desired level of automation, and the specific cutting requirements of your market.

Whether your focus is on fully automated high-capacity processing or cost-effective manual operation, Meitech offers smart solutions for every stage of your production process.

Want help finding the best model for your needs?

Talk to one of our specialists: https://meitech.com.br/en/contato/